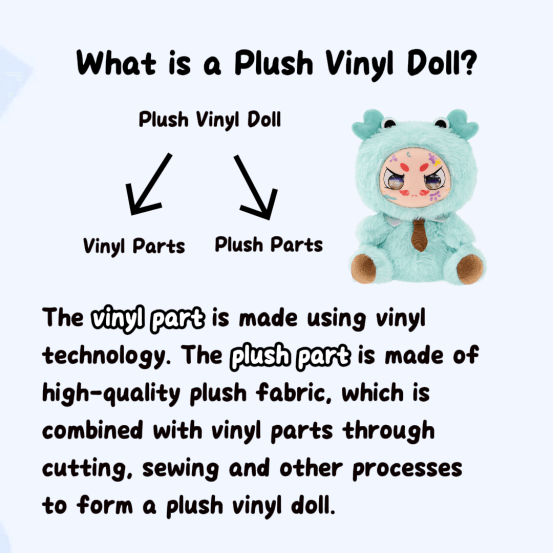

The plush vinyl doll is composed of a vinyl part and a plush part. The vinyl part is made by vinyl technology, and then combined with the plush part to get a plush vinyl doll.

Manufacturing process: Vinyl molding is a thermoplastic molding process. First, liquid PVC (polyvinyl chloride) plastic raw materials are injected into the mold cavity, and the plastic is heated and solidified in the mold. After cooling, demolding can obtain ethylene-based parts of various shapes. These parts are soft in texture, smooth in surface and have a certain elasticity. They are often used to make detailed parts such as the head, hands, and feet of dolls, and can accurately present complex shapes and rich expressions. For the plush part, high-quality plush fabrics are selected. Through cutting, sewing and other processes, soft materials such as cotton are wrapped and filled, and combined with ethylene-based parts to give the doll a soft touch and warm visual experience.

Advantages:

The vinyl process can produce a variety of complex shapes and models. Because the liquid vinyl can fit the shape of the mold very well. Whether it is a cartoon image with many details or a product with special curves and structures, it can be produced with a suitable mold.

Customization process

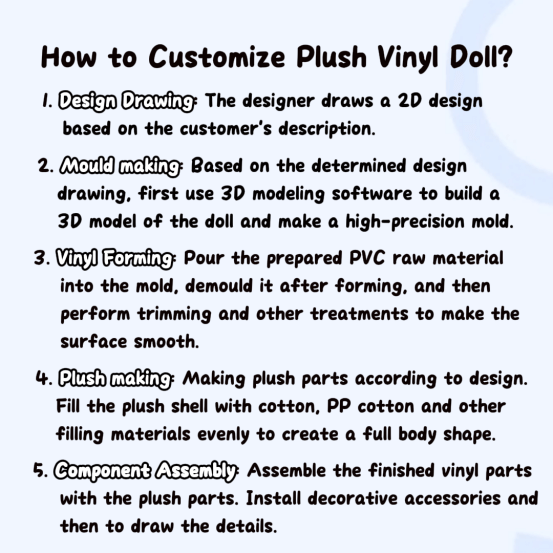

1. Creative conception and design: The customer first determines the theme of the doll, such as anime characters, pet images or original IP. Then, professional designers draw 2D design drawings based on the customer’s description, carefully outline the overall outline of the doll, facial features, body movements and color matching, and communicate and modify repeatedly until the customer is satisfied.

2. Mold production: According to the confirmed design drawings, high-precision molds are produced. First, the 3D model of the doll is constructed using 3D modeling software, and then the mold prototype is produced through 3D printing or CNC machining. After fine processing such as grinding and polishing, the silicone mold or steel mold is reproduced. The quality of the mold directly affects the molding effect of the doll.

3. Vinyl molding: Pour the prepared PVC raw materials into the mold and heat it in the oven. The temperature and time must be precisely controlled during the heating process to ensure that the plastic is evenly heated and fully cured. After molding, demoulding is performed, and the Vinyl parts are trimmed and deburred to remove defects, making the surface smooth and the shape regular.

4. Plush production and filling: Make the plush part according to the design. Fill cotton, PP cotton and other filling materials evenly into the plush shell to shape the full body and ensure soft and comfortable touch. When filling, pay attention to control the filling amount to avoid too full and too hard or too little and collapsed.

5. Assemble the parts: Assemble the finished vinyl parts with the plush body accurately and fix them with stitches or glue. Install decorative accessories such as eyes, nose, mouth, etc., making sure they are firm and in the right position to add vivid expressions to the doll.